A non-intrusive sensor that can prevent damage and costly shutdowns at your plant

- Monitoring of particles commonly found in the oil we use to cool, clean and lubricate machines

- Early indicators of incipient damage are easily identified

- The particle scanner classifies debris by size

- Allows for the early detection of progressive damage to gear teeth and roller bearings

- Easily mounted, the online particle counter features a patented method for detecting particles and contaminants in real-time

Click to see full product description from Pruftechnik

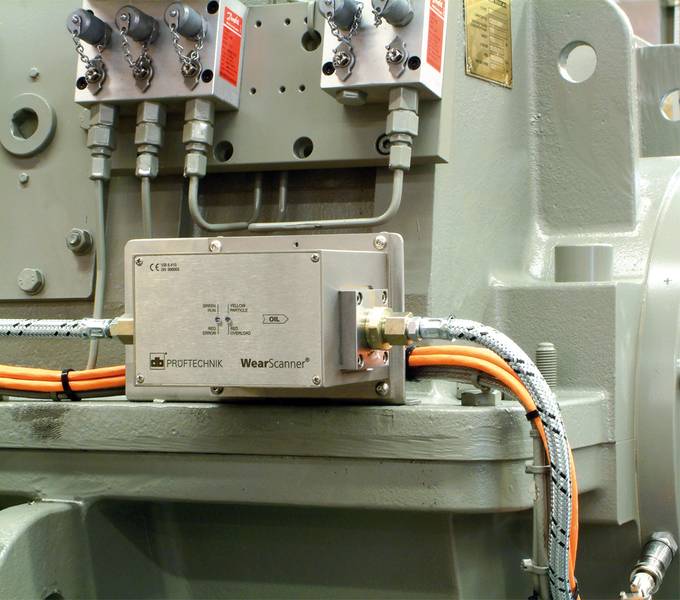

Monitoring particles commonly found in the oil we use to cool, clean and lubricate machines allows for the early detection of progressive damage to gear teeth and roller bearings. With the particle counter from PRUFTECHNIK, early indicators of incipient damage are easily identified, measured and classified using an intuitive online system.

WEARSCANNER® is a non-intrusive sensor that can prevent damage and costly shutdowns at your plant. Easily mounted, the online particle counter features a patented method for detecting particles and contaminants in real-rime. The data is then relayed to you via ModBus or CMS. The particle scanner classifies debris by size according to ISO 16232, which makes trend monitoring and maintenance straightforward for you.